Eddyfi Services

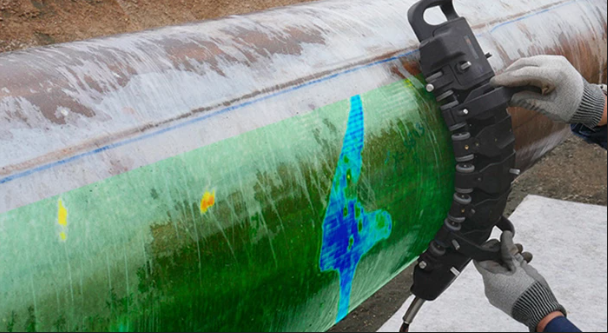

Spyne, an adaptable surface Eddy Current Array (ECA) screening tool, is specifically engineered to maximize productivity for the detection of Stress Corrosion Cracking (SCC) cracks, subsurface defects, and pitting in various critical components such as high-pressure gas pipes, vessels, tanks, pipelines, and more. With a higher PoD than MPI/PT and with its ultrafast capabilities, it paves the way to unprecedented efficiency.

Spyne is a revolutionary screening tool for surface-breaking cracks on pipelines. Much faster and reliable than traditional magnetic particle testing (MPI), it can accommodate a range of flexible probes designed to suit ferritic and non-ferritic alloys and be configured to inspect external diameters from 150 mm (6 in) to flat surfaces. It can detect individual cracks as small as 2 mm (0.080 in) long and 1 mm (0.040 in) deep, and colonies of cracks of virtually any depth and length.

The Spyne is encoded and has a coverage of 200 mm (8 in), maximum scan speed of 600 mm (24 in) per second, and optional magnetic wheels to facilitate scanning the sides and bottom of the pipe. Its raster scan capability allows recording the inspection of 100% of the pipe's external surface in a single datafile.

Applications

Stress Corrosion Cracking Direct Assessment on Pipelines

Magnetic Particle Inspection (MPI) has been the primary reference for Stress Corrosion Cracking (SCC) detection in pipeline integrity. Although relatively economical and easy to deploy, MPI is time-consuming and highly user-dependent. Recent field trials have proved that Spyne outclasses MPI in many aspects.

Offering an impressive speed, combined with an exceptional high Probability of Detection (PoD), Spyne transforms in-ditch inspections and provides greater control over the human factor. In addition to SCC, Spyne detects all linear indications breaking the outer surface of pipelines such as Hydrogen Induced Cracking (HIC), fatigue cracks, Lack of Fusion (LoF) in ERW and A. O Smith FW, hook cracks, etc.

Hard Spots on Pipelines

Hard spots result from a deviation from uniform quenching procedures during pipeline build, although a more prevalent manufacturing defect before 1970.

The sustained stress of internal operating pressure combined with the increased brittleness from hard spots found on a pipeline heighten its vulnerability to damage mechanisms, especially cracks, accelerating potential failure.

Changes in steel microstructure lead to significant property changes in the pipeline wall, making Spyne a perfect tool for hard spot detection. It provides a 360-degree map of hard spots and all cracks present along a pipe within minutes. Replacing nital etching and magnetic particles in a single scan demonstrates very well its higher efficiency over current techniques used in the field.

Cracks on High-Temperature Emulsion Pipelines

An emulsion pipeline essentially carries a mixture of bitumen, hot water, and steam. This critical asset is subject to intergranular stress corrosion cracking (IGSCC), the leading cause of emulsion pipeline incidents.

Given the length of these emulsion pipelines – multiple kilometers – and their high operating temperature up to 185°C/365°F, inspecting such assets represent a considerable challenge.

Combining high PoD, considerable time savings, and all advantages of going digital, Spyne is now the primary reference for emulsion pipeline inspection.

Early-Stage Detection of Chloride Stress Corrosion Cracking (CSCC) in Stainless Steel Assets

In some environments, Stainless Steel (SS) corrosion resistance is limited, making assets susceptible to external crevices and pitting, initiating points for chloride-induced stress corrosion cracking (CSCC).

Eddy Current Array (ECA) has proven to be a highly effective solution. Combining high resolution and sensitivity ECA can detect CSCC at its very early stage. The wide coverage contributes to carrying out reliable inspections at high speed, reducing shut down time and overall costs.

Other Applications

The versatile Spyne can be utilized on many surfaces and applications ranging from 150 mm (6 in) diameter to a flat plate. It is the ideal solution for ultrafast screening of large areas for the detection of surface-breaking flaws.

Storage tanks

LNG tank floors

Pressure vessels

Stainless steel tanks: food and beverage industry

Yellow Jacket™ piping

Corrosion underneath coatings