Mechanical Integrity

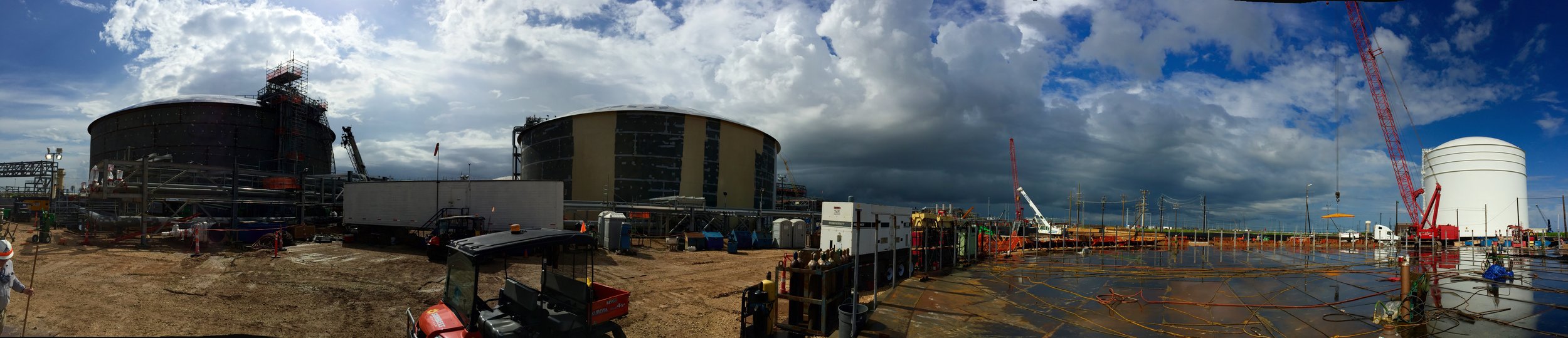

Integrity Specialists offers industry leading inspection services for upstream, midstream, and refining assets. Our goal is simply to help you stay online. Less down time and unexpected maintenance leads to a safer workplace and higher profit margins.

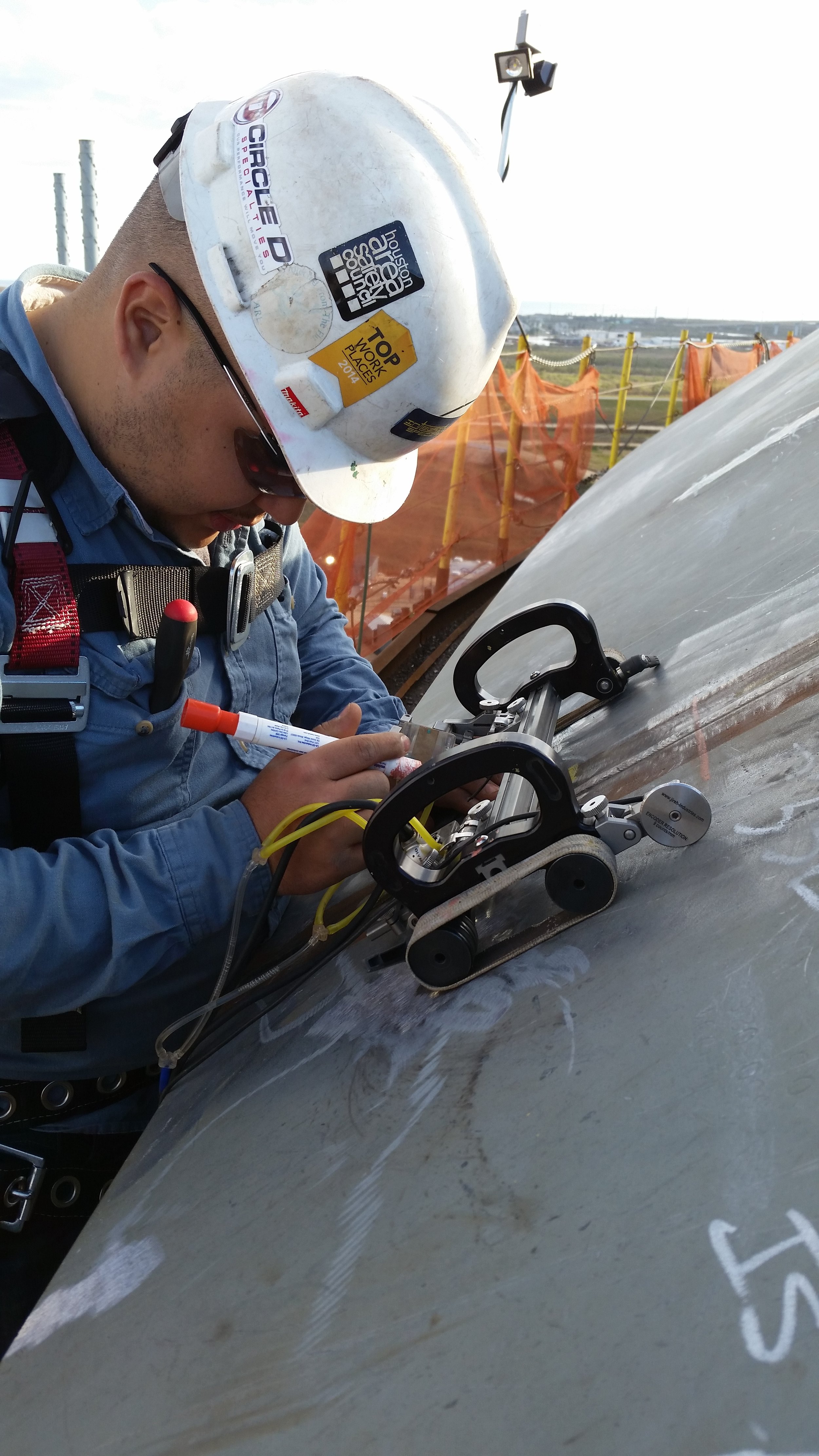

QA/QC Support

To ensure the highest quality finished product you need the highest level of quality control. For your new construction or repair projects, let us show the difference that our personnel can make.

Services

- UTT - Ultra sonic thickness inspections (manual and automated)

- UTS – Ultra sonic shear wave inspection of welds

- PAUT- Phased Array material and weld inspections – Manual or automated acquisition

- CUI – Corrosion under insulation

- MT/MPI – Magnetic Particle Evaluations – wet/dry, visible, and fluorescent

- PT/LPI – Dye penetrant evaluations – visible and fluorescent

- VT – Visual Inspection Programs

- API - American Petroleum Institute 653, 510, and 570 inspections of storage tanks, pressure vessels, and piping.

- AWS – American Welding Society – CWI – Welding inspections

- NACE – National Association of Corrosion Engineers – Coating and CP inspections

- PMI – Positive material identification

- Hardness testing

- Vacuum box weld evaluations

- MFL – Magnetic Flux Leakage – Tank floor inspections

- Laser Scan inspections of tank floors

- Fitness for service calculations – Customizable computerized reporting – Vessel management software