PRCI NDE-4C Material Verification

Basic steps:

Locate and document 2 quadrats of pipe 90 degrees opposed

Measure WT and circumference

Sand 0.004”-0.010” (Min 320 Grit)

Take chemical and carbon readings

Take hardness readings

Continue the polish to a mirror finish

Etch the surface

Gather microstructure pictures with microscope

Analyze Microstructure with software (Perciv)

Input all results into checkmate

Complete final report

Information gathered in-field during method:

Metallurgical Characteristics

• Grain Size

• Pearlite Volume Fraction

• Inclusion Volume Fraction – Correlation to ToughnessChemical Analysis

• Carbon %

• Silicon, Sulfur, Manganese, Phosphorous, Silicon, Aluminum, Chromium, Molybdenum, CopperHardness, Strength and Toughness Values

Pipe Geometry

• The smaller the pipe, the more erratic the transverse charpy test results

• Seam welded pipe-often rolled and hydrostatically expanded to achieve final dimensions (work hardening)

Advantages:

Performed well in PRCI round robin study against other methods

Lower equipment costs

More trained technicians

Can perform anomaly investigation and material verification at the same time

Can confirm material grade of in-service pre-1980’s pipe

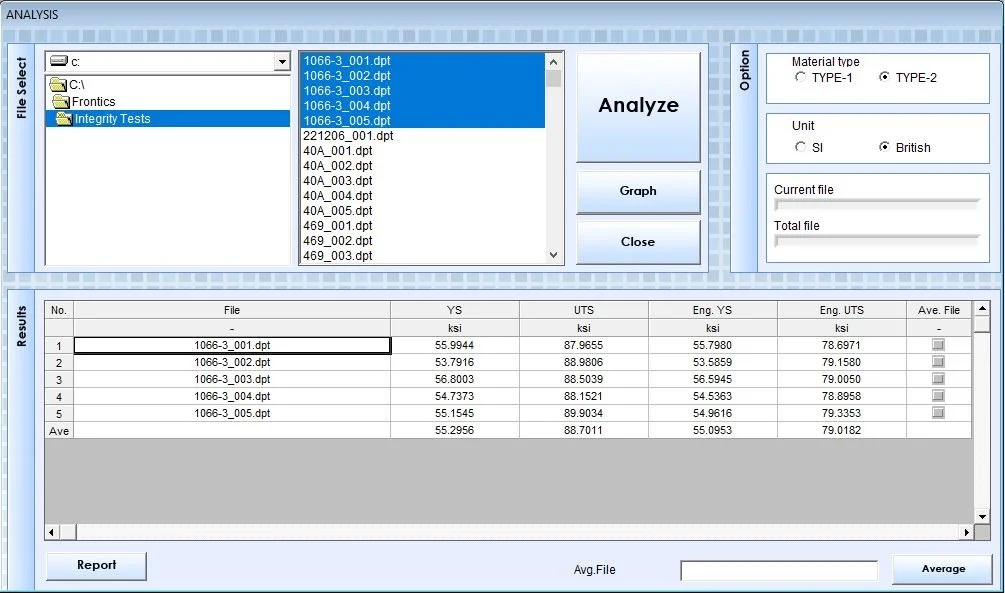

FRONTICS Material Verification

Tensile properties software based on the theory of IIT (Instrumented Indentation Technique) - evaluation items: yield strength, tensile strength, work-hardening exponent, elastic modules

Possible to measure and analyze in real time by using a laptop

Possible to load All-in-one software (Fracture Toughness Test, Hardware Test software)

Possible to perform all things such as testing, analyzing, collecting DB and making a report with one software

Batch analyzing function for multiple data sets

Instantaneous results

Can analyze pipe grade of in-service pipe of all vintages

In-situ metallography is not required